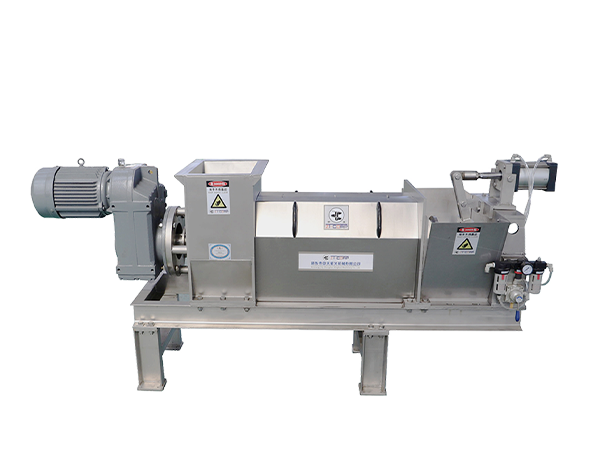

Screw Press Machine Revolutionizes Vegetable Waste Dewatering Industry

Zhongtian Xinghuo Machinery's Screw Press Machine Revolutionizes Vegetable Waste Dewatering Industry

With the rapid development of vegetable processing industries, the volume of residual vegetable waste has significantly increased. Improper handling of this organic waste not only occupies substantial storage space but also causes severe environmental pollution. As a national high-tech enterprise specializing in solid-liquid separation solutions, Xinxiang Zhongtian Xinghuo Machinery has developed an innovative screw press dewatering machine specifically designed for vegetable waste processing, addressing critical industry challenges.

【Innovative Technology for Efficient Dewatering】

The Zhongtian Xinghuo screw press employs advanced physical extrusion technology that eliminates the need for external heat sources, reducing energy consumption by up to 40% compared to conventional methods. Through precision engineering and mechanical simulation analysis, its helical screw design enhances axial thrust force by 35%, effectively resolving common operational issues including material slippage, bridging, and backflow. This optimization increases processing capacity by 28% per unit time while maintaining stable performance.

【Durable Design for Challenging Applications】

Specifically engineered for vegetable waste characteristics:

Wear-resistant coating on critical components extends service life by 2-3X

Wear-resistant coating on critical components extends service life by 2-3X

Alloy-reinforced screw blades withstand abrasive materials

Alloy-reinforced screw blades withstand abrasive materials

304 stainless steel construction ensures corrosion resistance

304 stainless steel construction ensures corrosion resistance

Acid/alkali-proof design adapts to various pH conditions

Acid/alkali-proof design adapts to various pH conditions

【Proven Performance in Practical Applications】

Field tests demonstrate exceptional results:

68-75% moisture reduction in vegetable waste

68-75% moisture reduction in vegetable waste

60% volume reduction for easier transportation

60% volume reduction for easier transportation

80% improvement in subsequent resource utilization efficiency

80% improvement in subsequent resource utilization efficiency

The dehydrated output proves ideal for organic fertilizer production or other recycling processes, significantly reducing disposal costs.

The dehydrated output proves ideal for organic fertilizer production or other recycling processes, significantly reducing disposal costs.

【Commitment to Sustainable Development】

As a leader in screw press technology, Zhongtian Xinghuo Machinery continues to invest in R&D to optimize equipment performance. Our next-generation screw press solutions will incorporate IoT-enabled smart controls and energy recovery systems, driving the solid-liquid separation industry toward greener and more sustainable development.

Why Choose Zhongtian?

✓ 18 years of solid-liquid separation expertise

✓ Customized solutions for 50+ material types

✓ Energy-saving designs reducing OPEX by 40%

✓ Achieve Your Waste Management Goals

Contact our engineers today to schedule a free material test and discover how our screw press technology can optimize your operations.

Contact Our Screw Pressing Experts Today!

☎ +86- 17837359619

✉ ztxhmachinery@163.com

[China with Screw Press Solution!]

With the rapid development of vegetable processing industries, the volume of residual vegetable waste has significantly increased. Improper handling of this organic waste not only occupies substantial storage space but also causes severe environmental pollution. As a national high-tech enterprise specializing in solid-liquid separation solutions, Xinxiang Zhongtian Xinghuo Machinery has developed an innovative screw press dewatering machine specifically designed for vegetable waste processing, addressing critical industry challenges.

【Innovative Technology for Efficient Dewatering】

The Zhongtian Xinghuo screw press employs advanced physical extrusion technology that eliminates the need for external heat sources, reducing energy consumption by up to 40% compared to conventional methods. Through precision engineering and mechanical simulation analysis, its helical screw design enhances axial thrust force by 35%, effectively resolving common operational issues including material slippage, bridging, and backflow. This optimization increases processing capacity by 28% per unit time while maintaining stable performance.

【Durable Design for Challenging Applications】

Specifically engineered for vegetable waste characteristics:

【Proven Performance in Practical Applications】

Field tests demonstrate exceptional results:

【Commitment to Sustainable Development】

As a leader in screw press technology, Zhongtian Xinghuo Machinery continues to invest in R&D to optimize equipment performance. Our next-generation screw press solutions will incorporate IoT-enabled smart controls and energy recovery systems, driving the solid-liquid separation industry toward greener and more sustainable development.

Why Choose Zhongtian?

✓ 18 years of solid-liquid separation expertise

✓ Customized solutions for 50+ material types

✓ Energy-saving designs reducing OPEX by 40%

✓ Achieve Your Waste Management Goals

Contact our engineers today to schedule a free material test and discover how our screw press technology can optimize your operations.

Contact Our Screw Pressing Experts Today!

☎ +86- 17837359619

✉ ztxhmachinery@163.com

[China with Screw Press Solution!]

RECENT POSTS

-

Zhongtian screw press redefines the distillers' grains processing technology

-

The application advantages of Zhongtian Xinghuo screw press in the citrus pomace processing industry

-

New solid-liquid separation technology - Dewatering Screw Press

-

Revolutionizing Pulp Dewatering

-

Physical Extrusion Technology in Fiber Material Dehydration

Application

-

Pineapples juicingRipe pineapples have a sweet taste and are one of the popular fruits. Pineapples deep processing is an effective way to increase earnings. Xinxiang Zhongtianxing Xinghuo Machinery Factory screw press dehydrator is involved in the processing of pineapple meat, pineapple rhizome, pineapple leaves and rotten pineapple.READ MORE >

Pineapples juicingRipe pineapples have a sweet taste and are one of the popular fruits. Pineapples deep processing is an effective way to increase earnings. Xinxiang Zhongtianxing Xinghuo Machinery Factory screw press dehydrator is involved in the processing of pineapple meat, pineapple rhizome, pineapple leaves and rotten pineapple.READ MORE > -

.jpg) Chinese herbal medicine dewateringIn pharmaceuticals, screw press technology revolutionizes herbal residue treatment. Precision mechanical compression separates moisture efficiently, slashing residue water content. Dehydrated residues are repurposed as fertilizer, enabling resource circularity and cost reduction.READ MORE >

Chinese herbal medicine dewateringIn pharmaceuticals, screw press technology revolutionizes herbal residue treatment. Precision mechanical compression separates moisture efficiently, slashing residue water content. Dehydrated residues are repurposed as fertilizer, enabling resource circularity and cost reduction.READ MORE >

More Application

.jpg)