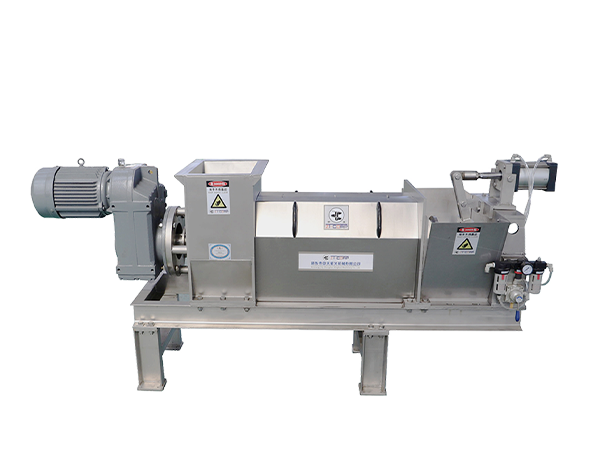

Summer Usage and Maintenance Guide for Dewatering Screw Press

The high-temperature and high-humidity environment in summer poses a severe challenge to the stable operation of Dewatering Screw Press. To ensure the efficient operation of the equipment, the following key maintenance measures must be strictly implemented, with the core lying in "cooling, moisture-proofing, frequent cleaning, and adjustment" :

1. Enhance heat dissipation and lubrication (cooling) :

Bearings and reducers: High temperatures accelerate the oxidation of lubricating oil. Increase the frequency of inspections (it is recommended to do so per shift or daily) to ensure that the oil level is normal and the oil quality is pure (free from emulsification, impurities and deterioration).

Motor: Ensure the unobstructed heat dissipation channel and strictly prevent the ventilation port from being blocked. Regularly monitor the operating temperature of the motor (using a thermometer gun or a touch-sensitive housing). When the temperature rises abnormally, stop the machine immediately to investigate (issues such as load, ventilation, voltage, and bearings).

2. Strictly prevent moisture erosion (moisture-proofing)

Electrical system: High humidity can easily cause short circuits, corrosion and moisture. Regularly check the sealing performance of the control cabinet, junction box, etc., to ensure that the sealing strips are intact and the door body is tightly closed. It is recommended to place desiccants in the control cabinet or install safe and compliant heating and dehumidification devices.

3. Prevent blockage and corrosion (Frequent cleaning)

Strictly enforce cleaning: Thorough cleaning must be carried out after each shutdown (regardless of the duration)! This is the lifeline of summer operation. Use appropriate tools (brushes, high-pressure water guns) to thoroughly remove all residues from the holes of the screen and the spiral blades to prevent accelerated clogging and corrosion.

4. Fine Monitoring and Operation (Adjustment) :

Operation status monitoring: Closely monitor the operation sounds of the equipment (abnormal friction and impact), current/power fluctuations (abnormal increase), and the continuity and uniformity of slag discharge. If any abnormality is found, stop the machine immediately for inspection and cleaning to prevent minor problems from worsening.

Avoid overloading operation: The heat dissipation burden of the equipment is heavy in summer. Strictly follow the rated processing capacity for feeding to prevent motor overload and overheating, as well as over-limiting or even damage to the screw spindle torque due to rapid or forceful feeding.

Fastener inspection: Changes in temperature and humidity can easily cause loosening. Regularly inspect and tighten the bolts of key parts (such as bearing housings, couplings, frame connection points, etc.).

1. Enhance heat dissipation and lubrication (cooling) :

Bearings and reducers: High temperatures accelerate the oxidation of lubricating oil. Increase the frequency of inspections (it is recommended to do so per shift or daily) to ensure that the oil level is normal and the oil quality is pure (free from emulsification, impurities and deterioration).

Motor: Ensure the unobstructed heat dissipation channel and strictly prevent the ventilation port from being blocked. Regularly monitor the operating temperature of the motor (using a thermometer gun or a touch-sensitive housing). When the temperature rises abnormally, stop the machine immediately to investigate (issues such as load, ventilation, voltage, and bearings).

2. Strictly prevent moisture erosion (moisture-proofing)

Electrical system: High humidity can easily cause short circuits, corrosion and moisture. Regularly check the sealing performance of the control cabinet, junction box, etc., to ensure that the sealing strips are intact and the door body is tightly closed. It is recommended to place desiccants in the control cabinet or install safe and compliant heating and dehumidification devices.

3. Prevent blockage and corrosion (Frequent cleaning)

Strictly enforce cleaning: Thorough cleaning must be carried out after each shutdown (regardless of the duration)! This is the lifeline of summer operation. Use appropriate tools (brushes, high-pressure water guns) to thoroughly remove all residues from the holes of the screen and the spiral blades to prevent accelerated clogging and corrosion.

4. Fine Monitoring and Operation (Adjustment) :

Operation status monitoring: Closely monitor the operation sounds of the equipment (abnormal friction and impact), current/power fluctuations (abnormal increase), and the continuity and uniformity of slag discharge. If any abnormality is found, stop the machine immediately for inspection and cleaning to prevent minor problems from worsening.

Avoid overloading operation: The heat dissipation burden of the equipment is heavy in summer. Strictly follow the rated processing capacity for feeding to prevent motor overload and overheating, as well as over-limiting or even damage to the screw spindle torque due to rapid or forceful feeding.

Fastener inspection: Changes in temperature and humidity can easily cause loosening. Regularly inspect and tighten the bolts of key parts (such as bearing housings, couplings, frame connection points, etc.).

RECENT POSTS

-

Zhongtian screw press leads a new era of solid-liquid separation

-

The customized screw press for foreign customers was loaded and dispatched

-

Professional manufacturer of screw press dewatering machines

-

Summer Usage and Maintenance Guide for Dewatering Screw Press

-

Customized ZTZY180 screw extrusion separator for export to Vietnam

Application

-

Kitchen waste treatmentHandling material: Kitchen waste; Capacity: 30t/d; Kitchen waste is generated in the process of cooking all kinds of vegetable scraps, bags, boxes, bottles, cans and other garbage. Among them, organic waste is perishable and easy to breed bacteria. And it doesn’t allowed to goes the back-end equipment. But food waste treated by spiral extrusion separator can achieve the effect which no water leakage when hold on treated materials in hand. Choose screw press dewatering machine, the energy consumption of equipment is greatly reduced.READ MORE >

Kitchen waste treatmentHandling material: Kitchen waste; Capacity: 30t/d; Kitchen waste is generated in the process of cooking all kinds of vegetable scraps, bags, boxes, bottles, cans and other garbage. Among them, organic waste is perishable and easy to breed bacteria. And it doesn’t allowed to goes the back-end equipment. But food waste treated by spiral extrusion separator can achieve the effect which no water leakage when hold on treated materials in hand. Choose screw press dewatering machine, the energy consumption of equipment is greatly reduced.READ MORE > -

.jpg) Pectin Material SeparationDesigned for sticky, agglomerative pectin-based materials (e.g., citrus peel, apple pomace), our technology overcomes clogging and inefficiency. Achieves 40% higher efficiency and 25% lower energy consumption vs. traditional methods.READ MORE >

Pectin Material SeparationDesigned for sticky, agglomerative pectin-based materials (e.g., citrus peel, apple pomace), our technology overcomes clogging and inefficiency. Achieves 40% higher efficiency and 25% lower energy consumption vs. traditional methods.READ MORE >

More Application

.jpg)

.jpg)