What do you think about when you plan to buy a screw extrusion dehydrator?(I)

What do you think about when you plan to buy a screw extrusion dehydrator?

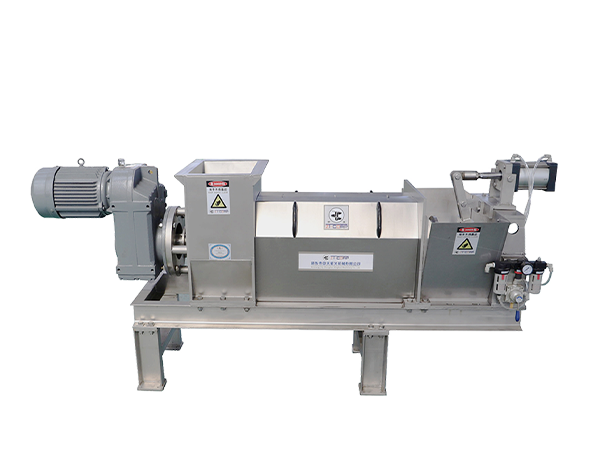

The spiral extrusion dehydrator is a continuous operation solid liquid separation equipment. It’s used for organic material extrusion liquid, inorganic material slag liquid separation. So, when you are going to purchase s spiral extrusion dehydrator, you need to pay attention to several key matters to ensure that the equipment can meet your production needs, so that helps to improve the dehydration efficiency, and ensure long-term stable operation.

In this article, we share the first thing to note: Clarify processing requirements.

1, the type of materials: First of all, you should clear the type of materials that need to be treated, such as vegetables, pulp, lees, herbs and so on. Different materials have different physical and chemical properties, such as particle size, stickiness, moisture content, etc., which will directly affect the choice of dehydrator and dehydration effect.

2, processing capacity: estimate the amount of material that needs to be processed per hour or per day, so that ensure the equipment can meet the production needs. Too much processing will lead to equipment overload operation, and too little processing will cause resource waste.

3, dehydration effect requirements: according to the production process on the water content of the dehydrated material requirements, you should choose the appropriate dehydrator model and configuration which we can help to do.

The spiral extrusion dehydrator is a continuous operation solid liquid separation equipment. It’s used for organic material extrusion liquid, inorganic material slag liquid separation. So, when you are going to purchase s spiral extrusion dehydrator, you need to pay attention to several key matters to ensure that the equipment can meet your production needs, so that helps to improve the dehydration efficiency, and ensure long-term stable operation.

In this article, we share the first thing to note: Clarify processing requirements.

1, the type of materials: First of all, you should clear the type of materials that need to be treated, such as vegetables, pulp, lees, herbs and so on. Different materials have different physical and chemical properties, such as particle size, stickiness, moisture content, etc., which will directly affect the choice of dehydrator and dehydration effect.

2, processing capacity: estimate the amount of material that needs to be processed per hour or per day, so that ensure the equipment can meet the production needs. Too much processing will lead to equipment overload operation, and too little processing will cause resource waste.

3, dehydration effect requirements: according to the production process on the water content of the dehydrated material requirements, you should choose the appropriate dehydrator model and configuration which we can help to do.

RECENT POSTS

Application

-

.jpg) Herbal/Flower DewateringCritical for preserving product quality and resource efficiency, our screw press employs advanced spiral-sieve synergy to extract moisture from botanicals while retaining integrity.READ MORE >

Herbal/Flower DewateringCritical for preserving product quality and resource efficiency, our screw press employs advanced spiral-sieve synergy to extract moisture from botanicals while retaining integrity.READ MORE > -

Pineapples juicingRipe pineapples have a sweet taste and are one of the popular fruits. Pineapples deep processing is an effective way to increase earnings. Xinxiang Zhongtianxing Xinghuo Machinery Factory screw press dehydrator is involved in the processing of pineapple meat, pineapple rhizome, pineapple leaves and rotten pineapple.READ MORE >

Pineapples juicingRipe pineapples have a sweet taste and are one of the popular fruits. Pineapples deep processing is an effective way to increase earnings. Xinxiang Zhongtianxing Xinghuo Machinery Factory screw press dehydrator is involved in the processing of pineapple meat, pineapple rhizome, pineapple leaves and rotten pineapple.READ MORE >

More Application

.jpg)

.jpg)