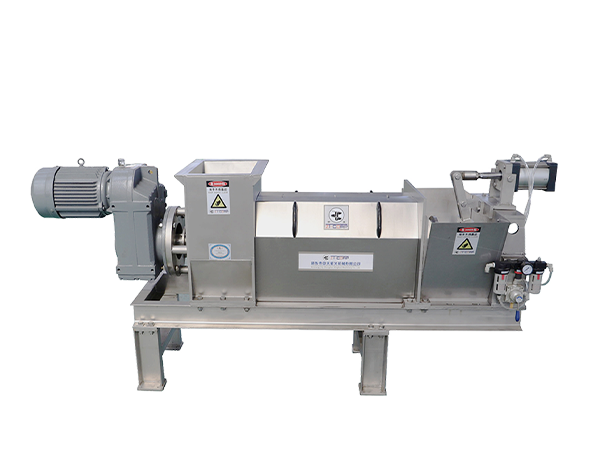

Using scope of spiral slag extrusion machine

Using scope of spiral slag extrusion machine

But all these industries can not get around a difficult problem which is the disposal of waste generated in the process of energy development. These materials need to be dehydrated in a timely manner, and then treated as fertilizer or waste after dehydration.

.jpg)

- Juicing various fruits and vegetables. Such as skin residue, sea buckthorn fruit, broken ginger and bamboo shoots.

- Dehydration of rice bran distillers after fermentation and cassava residue after biogas fermentation.

- The dehydration of gynostemma, stevia, cabbage, water hyacinth, celery, Chinese medicinal residue, chrysanthemum, etc.

- The dehydration of wood, wheat grass, straw, reed, etc.

- The dehydration of farmers' market waste, kitchen waste and other environmental protection industry.

But all these industries can not get around a difficult problem which is the disposal of waste generated in the process of energy development. These materials need to be dehydrated in a timely manner, and then treated as fertilizer or waste after dehydration.

.jpg)

RECENT POSTS

.jpg)