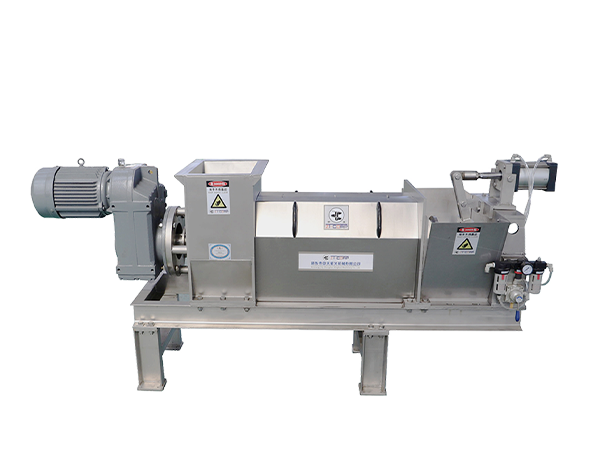

Screw press machine manufacturers share the using manual after purchasing

Our company produces a variety of different press equipment, the main products are screw press machine, screw juicer, screw dehydrator, etc. If you are interested, welcome to pay attention to our website, you can also leave a message or email, we will provide a detailed introduction.

After purchased screw press machine in three months, the new machine must be cleaned and replaced with new oil; Usually once a month or once a year; Add new oil must also be filtered with a filter; During operation, please ensure that the pressure of the pressure gauge does not exceed the warning line. Keep the system clean and airtight; Check whether there is oil leakage, temperature rise, air leakage, vibration, noise, insufficient pressure and other abnormal conditions, eliminate the cause in time; During maintenance, cleaning and replacement of parts, collision and damage should be avoided. Hammer should not be used to hit the fuselage.

Screw press machine has a widely application range. Which can be used for different solid-liquid separation. So that many industries would like to choose screw press equipment. We must do a good job of daily maintenance, so as to ensure the working effect and prolong using time.

After purchased screw press machine in three months, the new machine must be cleaned and replaced with new oil; Usually once a month or once a year; Add new oil must also be filtered with a filter; During operation, please ensure that the pressure of the pressure gauge does not exceed the warning line. Keep the system clean and airtight; Check whether there is oil leakage, temperature rise, air leakage, vibration, noise, insufficient pressure and other abnormal conditions, eliminate the cause in time; During maintenance, cleaning and replacement of parts, collision and damage should be avoided. Hammer should not be used to hit the fuselage.

Screw press machine has a widely application range. Which can be used for different solid-liquid separation. So that many industries would like to choose screw press equipment. We must do a good job of daily maintenance, so as to ensure the working effect and prolong using time.

RECENT POSTS

Application

-

Pineapples juicingRipe pineapples have a sweet taste and are one of the popular fruits. Pineapples deep processing is an effective way to increase earnings. Xinxiang Zhongtianxing Xinghuo Machinery Factory screw press dehydrator is involved in the processing of pineapple meat, pineapple rhizome, pineapple leaves and rotten pineapple.READ MORE >

Pineapples juicingRipe pineapples have a sweet taste and are one of the popular fruits. Pineapples deep processing is an effective way to increase earnings. Xinxiang Zhongtianxing Xinghuo Machinery Factory screw press dehydrator is involved in the processing of pineapple meat, pineapple rhizome, pineapple leaves and rotten pineapple.READ MORE > -

.jpg) Solid-liquid separation of granular/ powdered materialsSpecialized screens isolate solids (particles/powders) from liquids, enabling precise separation for industrial applications.READ MORE >

Solid-liquid separation of granular/ powdered materialsSpecialized screens isolate solids (particles/powders) from liquids, enabling precise separation for industrial applications.READ MORE >

More Application

.jpg)

.jpg)